FAQ

Environmental impact

What kind of fuel cells will be used?

The project will use solid-oxide fuel cells (SOFC) that operate at temperatures in the range of 500-1000°C, at high efficiency. SOFC technology is used mainly in land-based power plants with electrical capacities up to 10 MW, and as residential combined heat and power systems using natural gas fuel. The ShipFC will develop a compact SOFC system specifically for maritime use.

Why is green ammonia a good alternative to traditional fuels?

As ammonia contains no carbon, it does not emit CO2. It has the potential to be a zero-emission fuel, but this depends on the production method: whether we make grey, blue, or green ammonia. Grey ammonia is produced using energy from fossil fuels, thus emitting large amounts of carbon. Blue ammonia is produced using the same method, but emissions are reduced by carbon capture and storage (CCS). Green ammonia is the only zero-emissions alternative. When making green ammonia, hydrogen is produced using renewable, zero-emissions energy.

Project partner Yara has several ongoing projects for green ammonia production, for example using hydropower at the plant in Porsgrunn, Norway, wind power in Sluiskil, Netherlands, and solar power in Pilbara, Australia.

What are the emissions from the use of ammonia in the ShipFC-project?

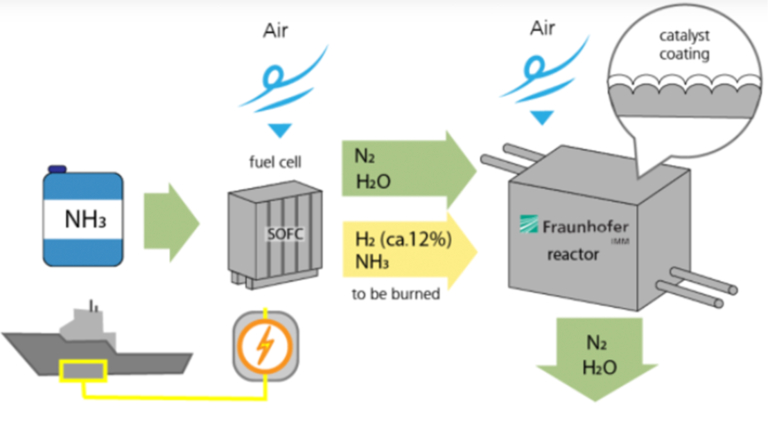

The process of generating electricity from ammonia is similar to that of a hydrogen-based power plant. Ammonia (NH3) is fed into the fuel cell anode. The air is fed into the fuel cell cathode, allowing the ammonia to be oxidized and form water and nitrogen at the anode side. This produces electrical energy. The gas stream leaving the anode contains water, nitrogen, a minor amount of hydrogen, and possibly a negligible amount of unconverted ammonia.

This residue is then fed into the catalytic converter developed by Fraunhofer IMM. Here, the air is introduced, and the residue comes into contact with a catalyst layer deposited onto the internal surface of the reactor. This triggers a chemical reaction. Ultimately, the only end products are water and nitrogen. An optimal reaction process will produce no or only negligible amounts of environmentally harmful nitrogen oxides.

Project technology

When will the FC technology be market-proven and commercially available?

The technology is being prepared for commercial deliveries in parallel with the progress in ShipFC, aiming to be able to have the first commercial deliveries just after the ShipFC demonstration in 2024/2025.

What are the main differences between using an FC and a traditional combustion engine?

A fuel cell electrochemically converts the chemical energy available in the fuel to electricity, without combustion. This enables higher electrical efficiency while operating with lower peak temperatures which have a positive effect on NOx production. As the Solid Oxide Fuel Cell can operate directly on ammonia there will be no CO2 emissions.

How long is the expected lifetime of a FC system, compared to combustion engines?

The fuel cell stack will have a certain loss of performance over time, depending on the operational profile and purity of fuel and air. Therefore, to ensure operation at high efficiency during the typical lifetime of a vessel, the stacks will be replaced with fresh stacks at a certain interval. The interval will depend on the operational profile and future stack improvements but will be at a minimum the duration of a regular major maintenance interval of a commercial vessel, typically every 5 or 7 years.

Can the FC technology be retrofitted to ships with traditional engines or does it require custom newbuilds?

The fuel cells are modular units that can be placed at different locations in a vessel, enabling both retrofit (as for Viking Energy) or newbuilds. Vessels that already have installed electric propulsion systems (or with significant auxiliary power demand) will be easier to retrofit than vessels with mechanical drive.

How is the fuel efficiency of a FC compared to that of a combustion engine?

The targeted fuel cell electrical lower heating value efficiency is around 60 % at maximum load, and towards 70 % at part load, when operating on ammonia. In addition, the system produces high-value heat that can be utilized in different ways to further increase the overall efficiency, depending on the vessel type.

Why is ammonia chosen over hydrogen for this vessel?

Space/ weight considerations related to storing large quantities of H2 on ships have generated interest in exploring alternative hydrogen-based energy carriers. Several studies have pointed to ammonia (NH3) as a potential fuel for shipping.

Ammonia is traded on a global scale, mainly as agricultural fertilizer. Approximately 130 ports have the infrastructure to receive, store and load ammonia as cargo.

Why use fuel cells and not directly use the fuel in the combustion engine?

Several ongoing projects are exploring the use of ammonia in combustion engines, but in this particular project we aim to validate the use of large-scale solid oxide fuel cells. Fuel cells are interesting due to the increased efficiency which in turn can help compensate for the lower energy density of ammonia compared to fossil fuels.