A critical factor for the viability of high temperature ammonia fuel cell systems for maritime use is that formation of NOx gases is managed and prevented as far as possible. In ShipFC Fraunhofer IMM will develop a compact catalytic afterburner, specifically dedicated to ensuring minimised NOx emissions.

A key part of the ShipFC project is to retrofit offshore supply vessel Viking Energy with 2MW ammonia fuel cells. Although proven on a small scale, using ammonia with fuel cells has never been implemented in a large-scale ship power system. A key innovation in the project is thus the development of a new fuel system for the vessel.

Development of the fuel system is led by Wärtsilä’s gas solutions division, building on leading experience in comparable fuel systems, as well as smaller-scale initiatives on ammonia. The fuel cell system will be developed by Prototech. The 2MW system will not have any direct GHG emissions, and specific activities are planned to also ensure prevention of NOx, SOx, or particles emissions.

Project Coordinator Tore Boge of NCE Maritime CleanTech says: ”ShipFC aim to demonstrate a fuel cell system for shipping capable of removing GHG and reducing NOX, SOX and particulate matter by at least 80% compared to conventional diesel-based solutions. A key task in the development work is thus to ensure that formation of NOx gases is managed and prevented as far as possible”-,

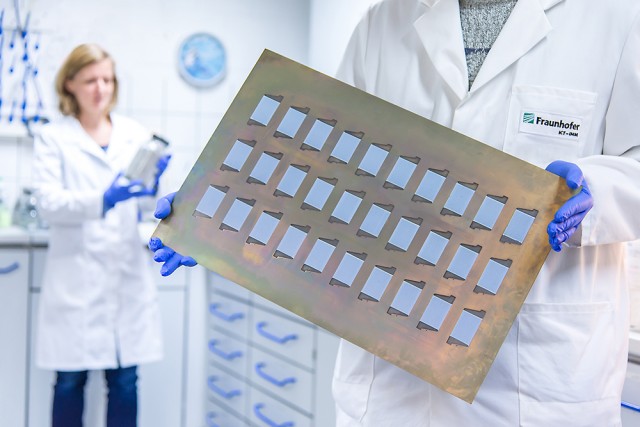

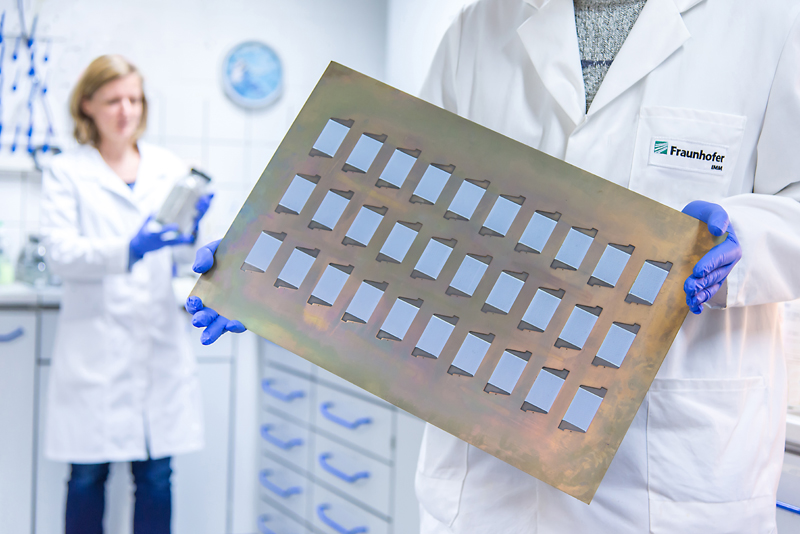

A key NOx prevention and mitigation action include the development, design and manufacture of a compact catalytic afterburner that will minimize such emissions. The development work will be led and performed by German research institution Fraunhofer IMM that has about 20 years of experience with burner/reformer development.

“In relation to increasingly stringent requirement for international shipping it is considered a key benefit that fuel cells operate at lower temperatures than potential ammonia combustion engines, which increases the likelihood that NOx emissions can be managed properly. However, it is essential that critical components such as a fuel afterburner is designed so that temperatures and flow compositions can be easily controlled, and further that the NOx content in the exhaust can be minimised”, Dr. Helmut Pennemann of Fraunhofer IMM says.

The institution’s work in the project specifically deals with the treatment of SOFC off-gas to convert hydrogen and the remaining ammonia into water and nitrogen. The aim is to ensure full conversion particularly of the remaining ammonia in the SOFC off-gas without forming NOx. The final result will be a reactor for the off-gas treatment that will be integrated in the fuel cell system installed on board Viking Energy.

First results available this year

Since an experimental determined composition of the SOFC off-gas is not available the moment, Fraunhofer IMM has now started their experiments with a gas composition based on simulation results. The synthetic off-gas used contains hydrogen, nitrogen, water and 100 ppm of ammonia.

“This gas mixture is fed into a reactor where hydrogen and ammonia is converted to water and nitrogen, and the product gas compositions are to determine particularly the concentrations of ammonia and NOX. Catalytic performance of various catalysts will be tested at different temperatures, WHSV, and water concentrations. This allows us to identify the most suitable catalyst as well as suitable process conditions”, Dr. Pennemann explains.

The first results will be available this year, and they will provide important insights into catalytic performance, suitable process conditions for the off-gas treatment, and also key parameters for catalyst deposition. Finally, the results will put Fraunhofer IMM in the position to develop the reactor for off-gas treatment which will be integrated in the fuel cell system.